BELTDRAULIC™ = HYDRAULIC – FLUID + BELT

Beltdraulic provides higher speed capabilities compared to hydraulics, as well as exceptional control over displacement, speed, and various motion characteristics. It is an ideal solution when you require precise, smooth, and powerful actuation.

3X FASTER THAN HYDRAULICS

Beltdraulic has shock-absorbing accumulator abilities, which allow it to replace hydraulics in situations where screw-type actuators are not suitable.

SHOCK-LOAD CAPABLE

Beltdraulic is a completely fluid-free and passively cooled system. This addresses the significant demand for eliminating hydraulic and coolant leaks and spills by removing the need for hydraulic fluids and coolant.

With no high-pressure fluid to manage, maintenance is significantly easier than dealing with a comparable hydraulic solution. In fact, the replacement process typically takes less than 15 minutes from start to finish.

FLUID-FREE OPERATION

Beltdraulic enables full system efficiency agnostic of what the power source is. We are seeing lots of work on hydrogen electrolysis on commercial scale. If this were to become the dominant technology, electrified actuation as part of a hydrogen IC engine, RISE®Beltdraulic would be a good fit.

EMISSION FREE PERFORMANCE

LOW SOUND EMISSIONS

Beltdraulic products, built on the rolling contact efficiency, produce minimal sound power. This caters to the demand for actuators and machinery that do not disrupt normal conversation or create excessive noise.

ZERO UNCOMMANDED MOVEMENT

Beltdraulic products use direct drive belt power to securely hold loads with zero power use or drift, outperforming hydraulic systems over extended periods.

While Beltdraulic is designed for your machine's useful life, it is also equipped with connectivity features that enable remote monitoring of performance and product health. This allows for valuable operational data transmission, such as maintenance or fault conditions, cycle characteristics, force and position measurements, which other alternatives lack.

NO UNPLANNED DOWNTIME

Beltdraulic reduces power and fuel consumption by an impressive 65-90% compared to modern hydraulic systems, regardless of the energy source (e.g., diesel, CNG, hydrogen, or electric).

REGENERATIVE LOWERING

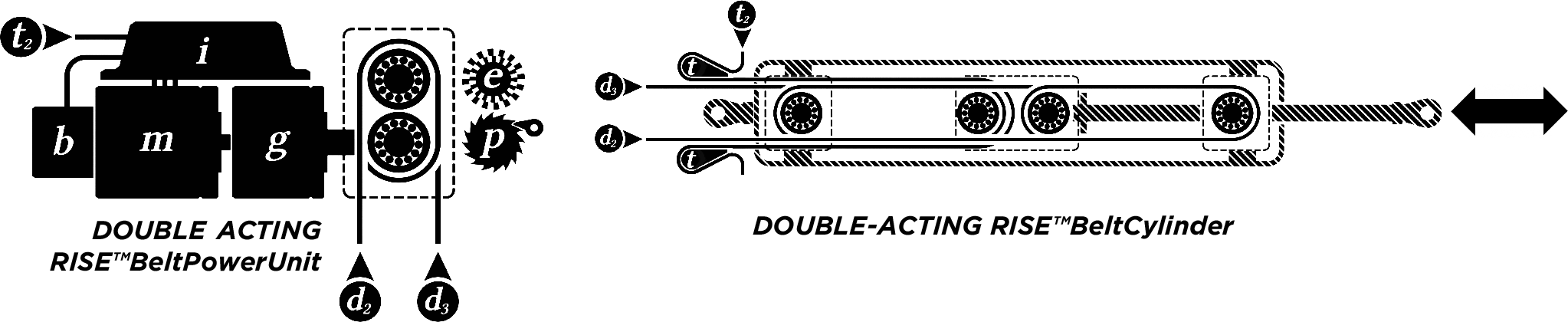

ACTING DIRECTIONS

Just like hydraulic cylinders, Beltdraulic come in two flavors; Single-acting and double-acting.

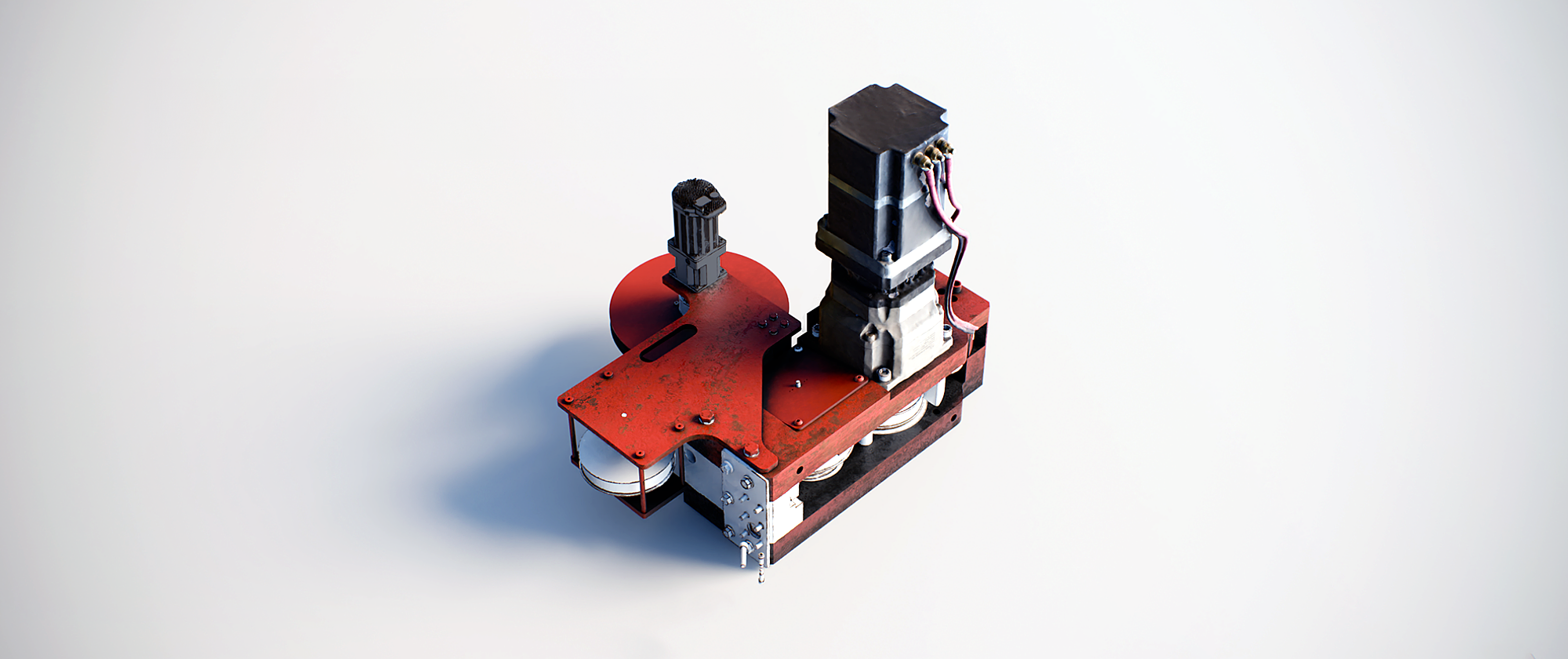

Our Beltdraulic technology harnesses powerful forces using a unique setup of RISE®Belts arranged like a block and tackle system inside RISE®BeltCylinder. Essentially, RISE®BeltCylinder works by having two sets of these block and tackle systems. These are positioned around a central RISE®BeltPowerUnit, allowing one set to feed into the other as it extends or retracts.

For different needs, we offer both single and double-acting RISE®BeltCylinders. Single-acting cylinders are simpler, using just one block and tackle set for applications where maximum extension or retraction is key.

Double-acting cylinders, on the other hand, use two sets for greater versatility and force acting in both directions.

Both types of cylinders incorporate a RISE®BeltPowerUnit to turn rotary motion into linear belt motion with one exception – The main difference between single and double acting RISE®BeltPowerUnit is whether this reservoir is used as a single acting cylinder will need to wind up the excess belt.

All RISE®BeltPowerUnit come equipped with essential components like inverters, motor brakes, gearboxes, and encoders, ensuring reliable and efficient operation across all our models.

Beltdraulic system revolutionizes machine design with RISE®BeltLine, allowing unparalleled flexibility in how machines are built and operated. This groundbreaking feature enables the transmission of linear belt force from the RISE®BeltPowerUnit to a RISE®BeltCylinder, regardless of their physical proximity. Imagine the adaptability of electrical wires or hydraulic lines, but for mechanical force – that's the convenience RISE®BeltLine brings to your designs.

What sets the RISE®BeltLine apart is its ability to convey full belt power across complex 3D spaces with six degrees of freedom, a feat previously unachievable with traditional flat belts. This innovation opens up new possibilities for machine layouts, enabling designers to

ROUTING FORCE WITH FREEDOM

place actuation points in optimal locations without the constraints of connecting the RISE®BeltPowerUnit directly at the cylinder's base.

This flexibility means machines can be more compact, more efficient, and capable of executing more complex movements and functions. The RISE®BeltLine overcomes the traditional limitations of belt systems or other hydraulic cylinder alternatives, offering a solution that is superior to wire rope in every aspect—without the restriction of having to keep belts within a single plane. Now, your designs can harness the strength, compactness and efficiency of belts in three-dimensional topologies, ensuring peak performance and versatility.

LOAD CLASSES

The Beltdraulic system is designed to accommodate a wide range of industrial needs, and is currently available in two distinct load classes to suit various application requirements: the 2 Metric Ton class and the 22 Metric Ton class. Each class is specifically engineered to provide optimal performance, durability, and reliability for its respective load range.

Both load classes are supported by our innovative RISE®BeltLine system, enabling unmatched flexibility in machine design and functionality. By offering these two distinct classes, the Beltdraulic product family meets a broad spectrum of industrial demands, ensuring that regardless of the task at hand, there's a Beltdraulic solution ready to enhance efficiency, safety, and performance.

2 Metric Ton Class

Tailored for precision applications requiring nuanced control and lighter loads, this class is perfect for intricate machinery, automation processes, and other scenarios where fine manipulation and movement are critical. Within this class, we offer a variety of sub-products, each designed to cater to different directional needs, ensuring that even the most complex tasks can be handled with ease and efficiency.

22 Metric Ton Class

Engineered for heavy-duty applications, this class delivers the power and strength needed for large-scale operations. Whether it's for construction machinery, industrial lifting, or any other scenario requiring significant force, the 22 Metric Ton class provides robust solutions. Similar to the 2 Metric Ton class, it features a range of sub-products tailored to various acting directions, ensuring versatility and adaptability for challenging environments.

STROKE

RISE®BeltCylinder redefines flexibility and efficiency in machine design with its unparalleled stroke length capabilities, setting it apart from traditional hydraulic and screw-based systems. Our innovative design comes in two load classes, each with a customizable stroke length to precisely match your needs.

The secret to our cylinders' exceptional performance lies in the advanced RISE®Beltdraulic technology, ensuring that, regardless of the stroke length, the efficiency and speed of operation remain consistently high. This is akin to the smooth and reliable movement seen in the elevator systems of the tallest skyscrapers.

Unlike screw-based actuators, which are limited by issues such as screw whip over longer distances, RISE®BeltCylinder maintain their integrity and speed, offering the fastest actuation available for extensive stroke lengths. This breakthrough opens up unprecedented possibilities in machine design, allowing for more innovative, flexible, and efficient configurations than ever before.

2 Ton (mt) Class

Offers an impressive stroke length range from a minimum of 51 millimeters (2 inches) to a maximum of 5080 millimeters (200 inches). This versatility caters to a wide array of applications, from delicate adjustments to substantial extensions, without compromising on performance.

22 Ton Class

Designed for more demanding tasks, this class provides an extraordinary stroke length range, extending from 51 millimeters (2 inches) up to 15,240 millimeters (600 inches). This capability is unmatched in the industry, enabling the handling of large-scale operations with ease and precision.

ROTARY INPUT

The core of the Beltdraulic system is its innovative 'pump box', powered by a rotary shaft input located on the RISE®BeltPowerUnit. This design translates rotary motion into linear belt action for the RISE®BeltCylinder with exceptional efficiency. Simply put, turning the shaft clockwise or counterclockwise directly controls the cylinder's movement in either direction. This direct coupling achieves a fixed ratio of rotary to linear motion output, akin to a screw mechanism, but with the added benefits of smoother, longer-stroke, more efficient operation and greater versatility.

Unlike traditional hydraulic power units, which rely on continuous rotation and valve controls to manage cylinder output, our system offers precise control through the

inherent design of the rotary input. This not only enhances efficiency but also expands the range of potential power sources beyond electric motors.

For example, it accommodates manual operation via a hand crank, meeting the needs of customers seeking alternative, non-electric driving methods.

Furthermore, both single and double acting configurations of the RISE®BeltPowerUnit are equipped with a natural override function. This critical safety feature enables operators to manually lower loads in the event of a power outage or emergency, ensuring an additional layer of safety and reliability for the system.

COMPARED

Hydraulic systems are renowned for their ability to generate high forces and accommodate long strokes, while performance screw-based systems, such as ball-screws and roller-screws, offer impressive forces with higher speed and precision. However, screw actuators have limitations: their fatigue life is significantly affected by loads, wear, corrosion, contamination, misalignment, and vibrations. Rapid speed changes under load or axial impacts can severely reduce their lifespan due to

metal-on-metal contact, leading to pitting and wear. Furthermore, screw actuators are restricted in stroke length by the phenomenon of 'whip' or resonance at high speeds, limiting their effectiveness for applications requiring long extensions. While hydraulic systems can absorb axial shocks using accumulators, implementing a similar shock-absorbing feature in screw systems is challenging and rarely done. This is where our RISE®Beltdraulic system stands out, merging the best aspects of hydraulics and screw mechanisms into a unified solution. It matches the force capabilities of both systems and surpasses them by achieving long, elevator-like strokes without the risk

of internal whip or resonance. Unique to RISE®Beltdraulic, our RISE®BeltAcumulators incorporate special belt terminations linked to mechanical spring mechanisms that act like Zener diodes, absorbing mechanical pressure at peak loads to maintain output stiffness without compromising system longevity. This allows RISE®Beltdraulic to handle various axial shock loads efficiently, emulating the hydraulic system's shock absorption capabilities but with enhanced stiffness and longevity. By integrating basic series elastic components, we can also mimic the elastic nature of hydraulic circuits, offering a versatile and robust solution unmatched by traditional systems.

COLLABORATIVE SOLUTIONS FOR OPTIMAL PERFORMANCE

At RISE Robotics, we prioritize collaboration and ensure our Beltdraulic product delivers unmatched benefits tailored to your application. We work closely with our clients for seamless integration, bringing advanced technology and a robust supply chain.