A recent series on the RISE™Inside podcast has us chatting with some of the companies contributing to the Small Business Startup Ecosystem and the success of RISE™Robotics.

Dassault Systèmes, with their solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) application, SOLIDWORKS is one such company that has been a part of the RISE™ DNA since before its inception.

Suchit Jain, Vice President of Strategy & Business Development for Dassault Systèmes SolidWorks Corp., and Arron Acosta, CEO of RISE™Robotics, discussed the relationship with host Justin Starbird.

"Dassault Systèmes, a French company, acquired SOLIDWORKS in 1998," shares Suchit. "In those days, it used to be mainframes, computers running CAD. It used to be only meant for the chosen few if you will. SOLIDWORKS' promise then was to bring the power of CAD, computers, and the design process to every engineer's desk. That was the promise. We have kept that all these years."

Since Dassault's acquisition of SOLIDWORKS in 1998, the company has transformed from simply a CAD application into a full-service platform offering complete product lifecycle experiences for designers, manufacturers, and customers.

"As we moved into the last 10 to 15 years, we realized that experiences are important," explains Suchit. "So we created a cloud-based platform called the 3DEXPERIENCE platform, which allows all of our applications and tools to connect so that the data is interoperable, allowing all team members to create and deliver an experience to consumers, including everything from concept and design to manufacturing, lifecycle management, and even sales and marketing.

"Today, we call ourselves the 3DEXPERIENCE company. Our job is to bring 3DEXPERIENCEs, and enable our customers to create those 3DEXPERIENCEs, in a virtual form, such that when they deliver them physically, they'll come out perfectly every time."

To provide these complete 3D experiences, SOLIDWORKS offerings include-

2D CAD with DraftSight 2D drafting - DraftSight enables you to meet your drafting, modeling, prototyping, manufacturing, and laser cutting needs.

Essential 2D design and drafting with a complete set of edit, design, and automation tools

Create, edit, view, and share 2D and 3D DWG files with productivity tools and an API

3D CAD - Intuitive 3D design and product development solutions help you conceptualize, create, validate, communicate, manage, and transform your innovative ideas into great product designs.

Create fast and accurate designs, including 3D models and 2D drawings of complex parts and assemblies

Design for cost and manufacturing with cost estimation tools and manufacturability checks

Interact with team members and control revisions with standardized data management tools

Eliminate errors and rework by using integrated motion and stress analysis tools

3DEXPERIENCE® WORKS - unites the entire ecosystem, allowing you to connect the people, applications, and real-time data from every aspect of your business in one connected universe.

Aggregate and organize product and business data into actionable information

Benefit from integrated cloud-based product data and lifecycle management

Securely share real-time information and collaborate to drive sustainable innovation

COLLABORATION - Collaborate with your team using integrated social tools. Engage with management, customers, suppliers, and other stakeholders throughout the product development process.

Cloud-Based Data Management and Collaboration

Built-in revision and version control with no additional IT investments

Digitally connect with stakeholders to elicit valuable feedback easily

View, markup, manage, and share designs from anywhere, at any time, and on any device

Create dashboards and communities to connect people and data in one place to empower collaboration

ELECTRICAL DESIGN - SOLIDWORKS Electrical solutions simplify electrical product design with specific tools for engineers and intuitive interfaces for faster embedded electrical system design.

Easily integrate your electrical schematics into 3D models

Minimize repetitive tasks associated with developing electrical schematics

Leverage a common database for ECAD and MCAD, ensuring consistency when creating documentation

Access an extensive electrical component and symbol library of industry-standard schematic symbols

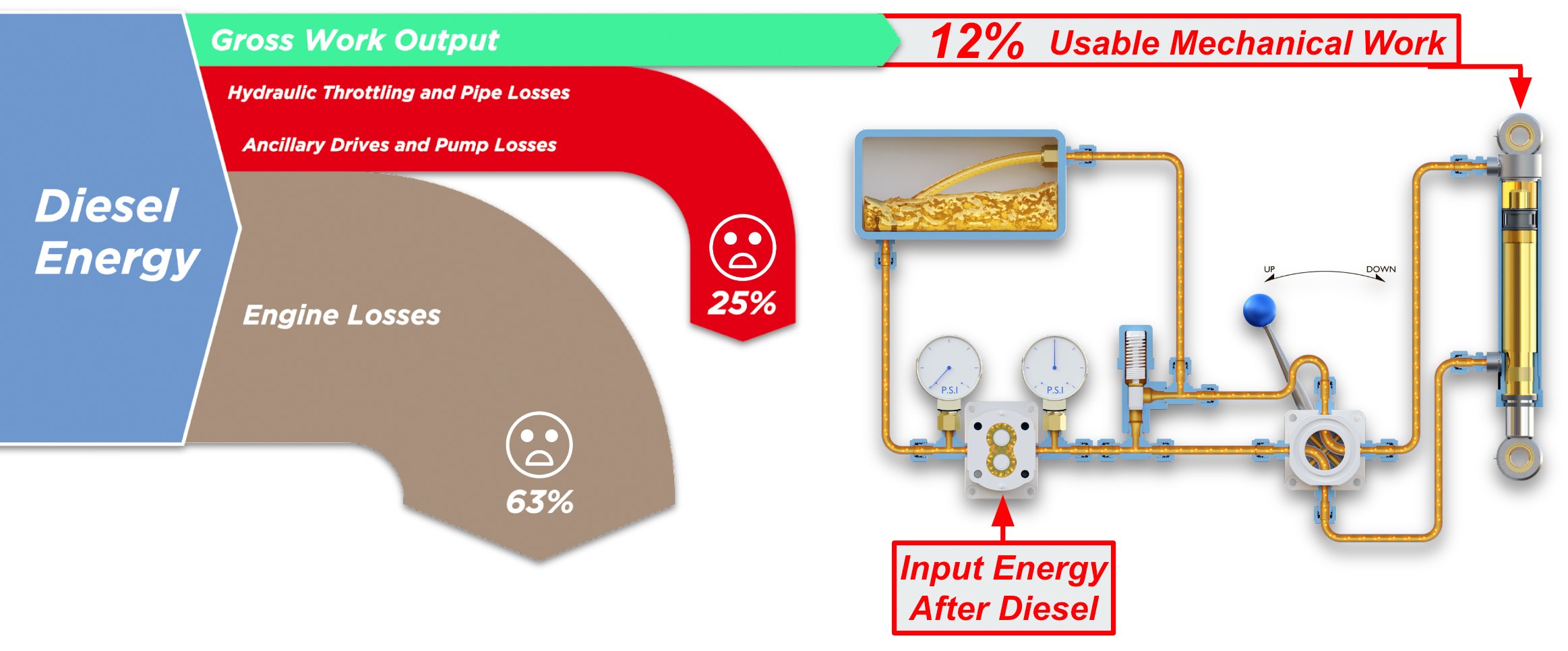

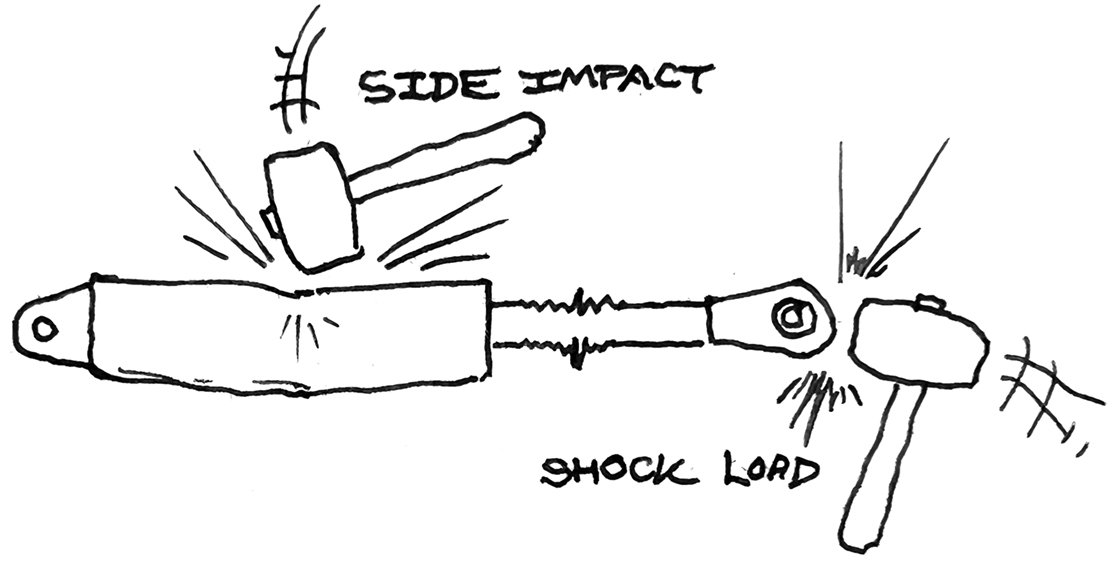

After years of working and designing with SOLIDWORKS, the RISE™Robotics team found themselves on the SOLIDWORKS 3DEXPERIENCE World stage in front of an audience of judges, designers, engineers, entrepreneurs, and business leaders pitching their revolutionary RISE™Cylinder, an electromechanical alternative to hydraulic systems, which catapulted them into the spotlight.

"At SOLIDWORKS World," Arron reminisces, "lots of customers discovered us for the first time, became aware of us, and started calling and emailing, wanting to see what would happen if they put our technology into their machines and we could show them by just providing them with a CAD model to fit right into their machine.

"One of the things that the CEO of Dassault Systèmes, Bernard Charlès, clearly understands is that Dassault Systèmes customers, SOLIDWORKS customers, are also RISE™ customers.

"This makes the collaborations that we do with original equipment manufacturers and hydraulic manufacturers very easy because we are all able to speak the same exact file language—it's like when you're doing Word editing, and everyone is using.doc, but in this case, it's all in SOLIDWORKS files."

Suchit adds, "In this world today, everybody collaborates. Parts are being purchased. You don't design everything. Sometimes you're buying parts; sometimes, you're getting them manufactured from outsourced places. The good news is, as a part of the 6 million user SOLIDWORKS network, we have a lot of people who are manufacturing and making things for other customers within the network with a common language: SOLIDWORKS files and data, which are now all on the cloud. Through the 3DEXPERIENCE platform, companies can exchange, very easily, all of that."

As for what's next for RISE™ and their relationship with SOLIDWORKS, "we're only midway through our journey with SOLIDWORKS," explains Arron.

"Next will be more licenses. We're growing pretty rapidly, building out our mechanical engineering team and building out our electrical engineering software manufacturing. We have triple the number of product projects that are starting now than we did previously. We will take on more licenses, set up more computers, and install SOLIDWORKS. That's the immediate need. Then, there's some farther-out stuff that's fascinating around making use of the other tools SOLIDWORKS offers for the rest of the life cycle of our products.

"As we journey into sustainment, we'll be there with SOLIDWORKS. It's nice to have great partners."

To learn more about SOLIDWORKS and their relationship with RISE™Robotics, listen to "SOLIDWORKS-The Language of Innovation" live on the RISE™Inside podcast.