Disability Pride Month occurs in the United States every July to commemorate the passing of the landmark Americans with Disabilities Act in July 1990. This civil rights law increased access and opportunities for people with disabilities in community life and employment and provided protections against discrimination.

The month aims to recognize the intrinsic worth and significant contributions of individuals with disabilities in our communities. According to America's Disability Community, the month is an opportunity to celebrate each person's uniqueness as "a natural and beautiful part of human diversity."

The celebration has received support from all around the world. It is beautifully exemplified by the mindsets and achievements of RISE™Robotics' very own Ken Gray, Chief Product Officer, and special guest, Michele Sullivan, a well-known author, TED speaker, leader, and advisor on social impact. Both have flourished and achieved enormous success while confronting their own particular hurdles, and they now seek to support and encourage workplace diversity while emphasizing its numerous advantages.

Among her many accolades, Michele was named one of the 50 most powerful women in philanthropy by Inside Philanthropy and served as a United States delegate to the United Nations Commission on the Status of Women. Today, she serves on the board of directors of ONE and chairs the Greater Peoria Local Initiatives Support Corporation Advisory Board.

Ken Gray

She also boasts a successful thirty-year career at Caterpillar, where she held various leadership positions, including Director of Corporate Social Innovation and President of the Caterpillar Foundation, the philanthropic arm of the manufacturing giant, where she helped to transform it into one of the world's most influential corporate foundations through the launch of the collaborative impact platform, Together. Stronger.

Upon her retirement in 2018, Michele released Looking Up: How a Different Perspective Turns Obstacles into Advantages, her story of overcoming childhood challenges, grueling surgeries, and the stigma of disability living with a rare form of dwarfism. Looking Up is a tribute to overcoming adversity with grace and strength and reminds us of the change we can all make in the world.

Michele, who stands at 4' tall, interprets the title Looking Up in 2 different ways. "I look up to most people literally, but I also look up to people figuratively because I believe we all have value," she says.

Both Ken and Michele believe firmly in recognizing and promoting the abilities, strengths, and immense value of diversity in the workplace.

Traditionally, people define diversity in terms of gender or race, but it goes further. Diversity also lies within thoughts and experiences. Individuals with disabilities make inherent problem solvers and innovative thinkers and give us the ability to see the world through a unique and valuable lens thanks to their particular journeys and challenges.

Our unique perspectives formed by the way we perceive our environment

Valuing our Vastly Different Perspectives

Michele explains, "I surrounded myself with people who had a dimension that I did not have and that the team needed. Whether it was how they were raised, if they paid their way through college themselves, or did they have three jobs? How people grow up makes them different. Where in the world have they grown up? In what circumstances? What experiences have they had?

"Someone who has worked their way up themselves, and I mean truly themselves, and someone who has had college paid for, never worked, and then went out for their first job, those two people are going to have vastly different perspectives.

"It tells you a lot about a person's gumption and initiative and what they would do when something doesn't go right. Do they panic? Or do they make the best of it? They have become successful in different ways, which has taught them other things.

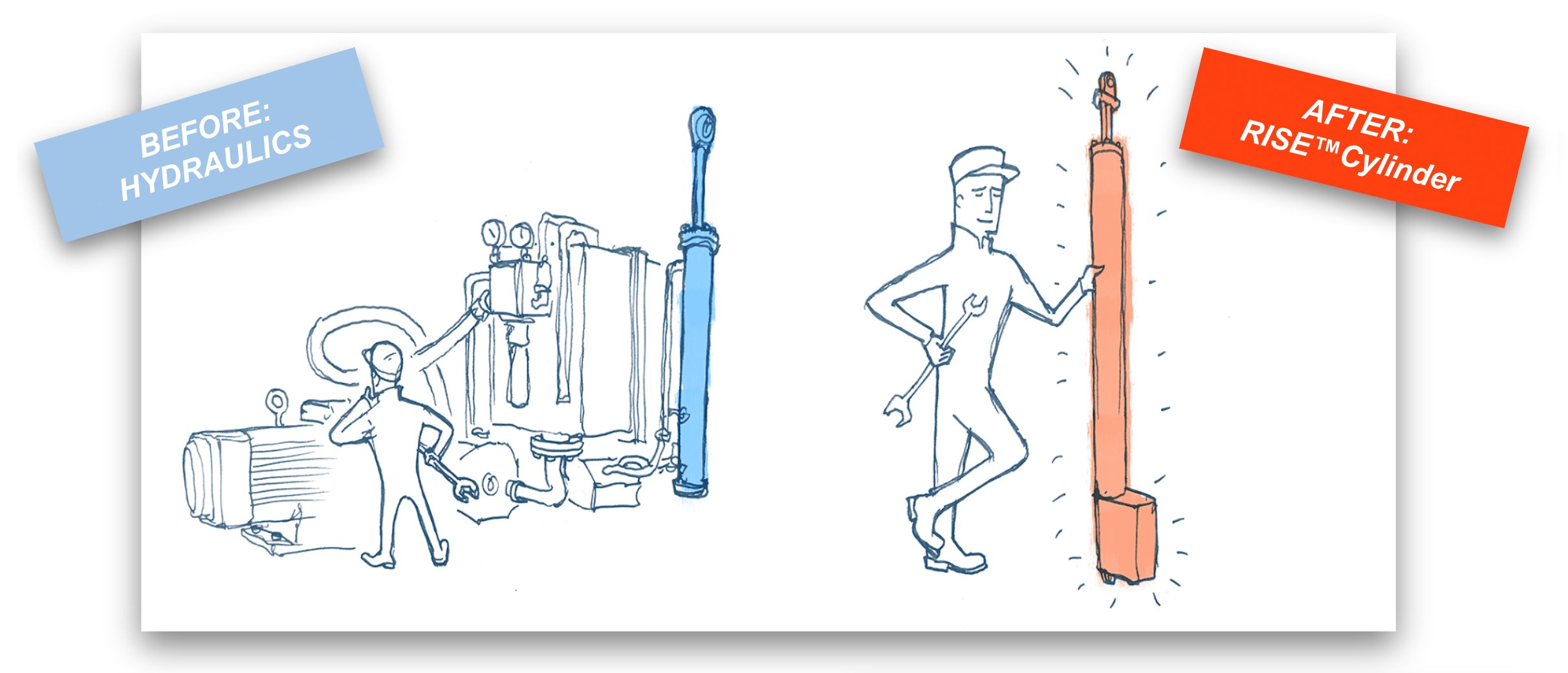

Gumption and Initiative

"At the end of the day, if everyone has the same background as me and looks like me, I don't have the best team."

Both Ken and Michele are adamant about the value that diversity can add to an organization and the necessity of fostering, appreciating, and supporting it in the workplace.

"It's amazing to me," says Ken, "that we don't recognize that diversity isn't valuable for diversity's sake, but also from a business standpoint. It's simply more valuable when you have a diverse team. The reason is the additional perspectives that people with diverse backgrounds bring. They bring a problem-solving mentality that they had to develop to get to these levels. To enjoy this level of success, you have to figure out how to solve problems on your own that others might not even perceive you to be having. You must be an innovator and a problem solver to get by. There is this mentality that many successful people with impairments have that I want to take advantage of as a business person, as a leader."

He adds, "There is an absolute, no-give-up, relentless spirit. There's just absolutely no give-up in people like this. I think that's a tremendous benefit for companies. We need to make sure that disabilities don't disqualify people from things that they can certainly do." Ken knows a thing or two about the resilience and tenacity it takes to succeed despite living with a disability in the workplace.

An Appearance of Diversity

"In my case," he shares, "I've been reluctant to tell my story because you can't tell by looking at me that I have a significant vision impairment or any other hidden issues. I've been very successful. Even people close to me would be surprised, I think, at how much discrimination there has been in my career, in my lifetime."

He shares, "I made sure that everybody knew during the interview process. It was very important to me that anyone who interviewed me for a role knew of my vision impairment because some accommodations were required.

"I was sent home on the first day of work. The doctor that did my physical on day one said, 'Well, Ken, we knew during the interview process that your eyesight was bad' and he paused, 'But we didn't know it was this bad.' They literally sent me home. They didn't have a job for me.

"We went from that arduous beginning to, over time, becoming director of the company. I have also run a couple of large, worldwide businesses for the last ten years of my career. "

"I do feel that part of the message that I want people to understand is that people with disabilities like mine or other disabilities that people can't see from the outside looking in can be successful. All that you need is an opportunity to be successful."

So what can companies do to diversify their workforce and open up opportunities for people with disabilities?

Ken says, "I just encourage people to hire people who are not like themselves. Make yourself look at what you can do to bring someone onto the team that has experience or a skill set that you simply do not have."

To do so, Michele suggests going out and learning about different associations and career programs. "Let college campuses and workshops know that you want diversity in possible candidates. If you have head hunters, tell them that you want a vast difference in thought, ability, and experience.

"You have to go out and make an effort. They're not going to come knocking on your door, necessarily," she explains.

Let prospective candidates know that your company is accommodating and welcoming.

Many employers today miss opportunities to put themselves out there, to be vulnerable, to say, "This is what we're looking for. We want to try this, and we're looking forward to what lies ahead."

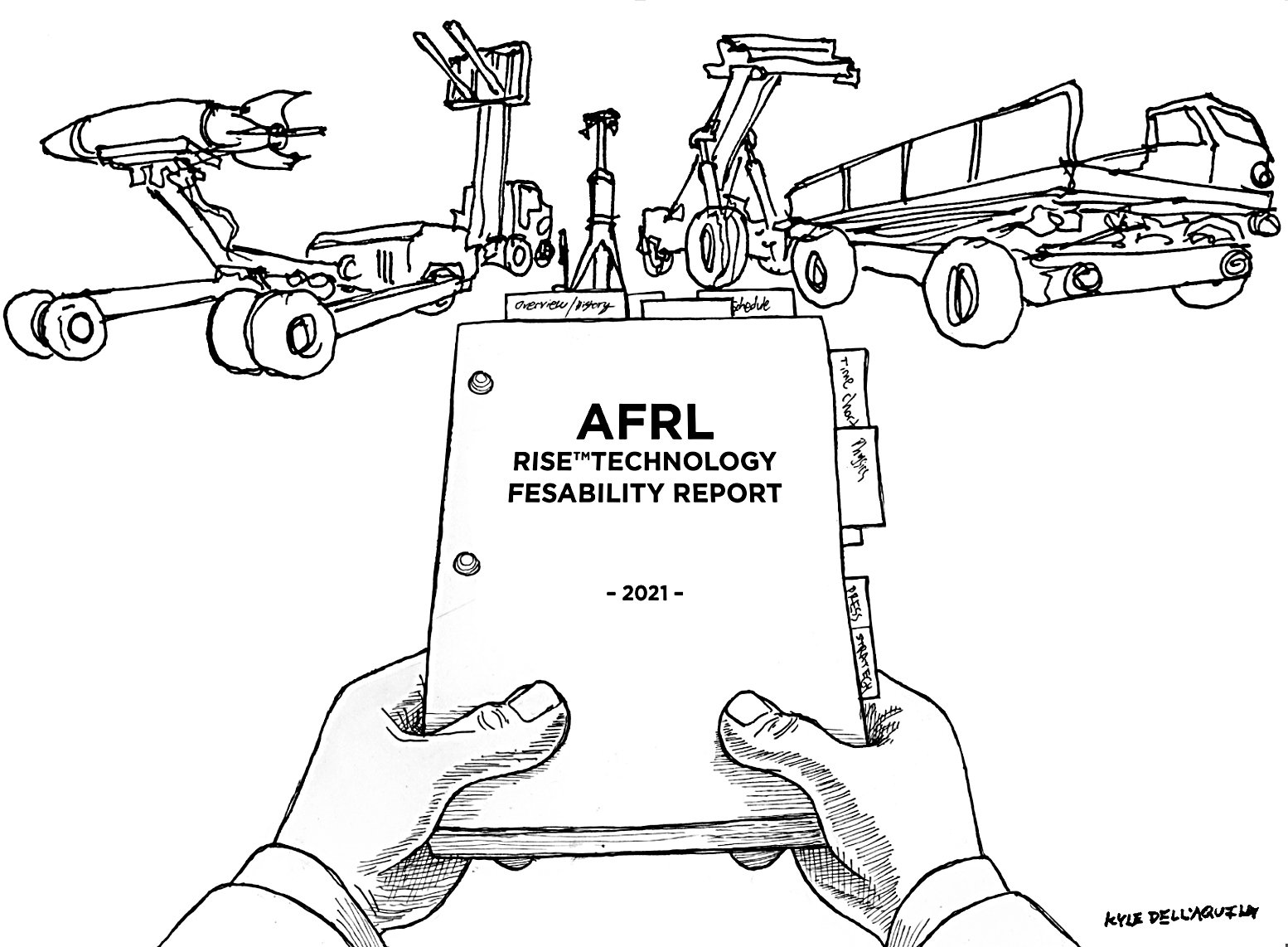

Leaving the World a Better Place

"Vulnerability is high-risk, isn't it? " Showing you're vulnerable is a high-risk, high-reward proposition," notes Ken.

Ultimately, it all comes down to working together, supporting each other, uplifting, celebrating, and empowering.

"If you think about it, think about one of your big successes or one of your small successes," Michele says. "Did you do everything by yourself?

"I can't think of one that I did all by myself.

"We always have people that help us. I think it's important that we reciprocate that every chance we get. That's one of the ways I say we have to leave the world a better place. You reach out to help people, offer to help, whatever that help is.

"In my Ted Talk, Asking for Help is a Strength, Not a Weakness, I call that 'you can't walk in somebody else's shoes, but you can walk along with them to support them.' That's what people have done for us, and that's what we've done for other people for many reasons.

“You can't walk in somebody else's shoes, but you can walk along with them to support them. That is called Humanity.”

"At the end of the day, that's called humanity.

"We have a lot of challenges in our society today where people think they know, and they don't. They are not open-minded. We really need to work on that and not be so judgmental because no matter where you go in the world, people want to thrive, and they want to support their families. They want to be successful. No matter what group I work with social impact-wise, they all want the same thing."

Michele Sullivan

"One of the biggest lessons of my career," adds Ken, "in all my travels around the world, one of the things I've learned is that people everywhere, no matter where they live, share far more similarities than differences. For some reason, we accentuate the differences."

"Someday, we'll get to a point where we're so inclusive that we won't have to have conversations like this. That's where Michele and I really want to get to. It is gradual, but it is changing. It is improving. We want to talk about this because we want to continue to encourage and support and reward that change toward more and more inclusiveness."

To hear more about Ken and Michele's inspiring journeys and efforts, listen to "We RISE™ with Michele Sullivan & Ken Gray" on the RISE™Inside podcast, live now!